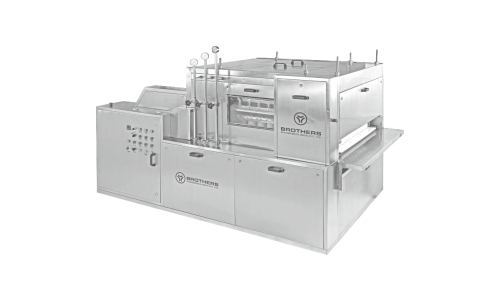

Washing and Air Jet Cleaning Machines

Air Jet Bottle Cleaning Machine Manufacturer

We are offering unique range in air jet vacuum cleaning machine, such as, linear vial washing machine, ampoule washing machine, rotary vial washing machine, high speed automatic rotary ampoule, linear tunnel bottle washing machine, rotary bottle washing machine, external vial washing machine.

To transfer the container to the cleaning segment air jet cleaning machine reach the separator assembly using the principle of the synchronized system of back-pressure of compartment sustained by the unscrambler.

A Washing and Air Jet Cleaning Machine is used to clean bottles, vials, ampoules, and containers before filling or packaging. It removes dust, particles, and contaminants using water, air jets, or a combination of both, ensuring high hygiene and safety standards.

An Air Jet Bottle Cleaning Machine is an advanced cleaning system that removes dust, debris, and contaminants from bottles using high-pressure air and vacuum suction, ensuring hygienic and dust-free containers before filling.

✔ Pharmaceutical Industry – For cleaning vials, ampoules, and bottles before drug filling. ✔ Food & Beverage Industry – Used for bottle washing before juice, water, or dairy filling. ✔ Cosmetic Industry – Cleans containers for lotions, creams, and personal care products. ✔ Chemical & Pesticide Industry – Ensures contaminant-free packaging.

The machine uses a compressed air jet system to remove fine dust and particles. Containers pass through multiple cleaning stations where high-pressure air blows out impurities, ensuring contamination-free packaging.

Yes, we offer customizable models based on production capacity, container type, and industry-specific requirements.

×

×