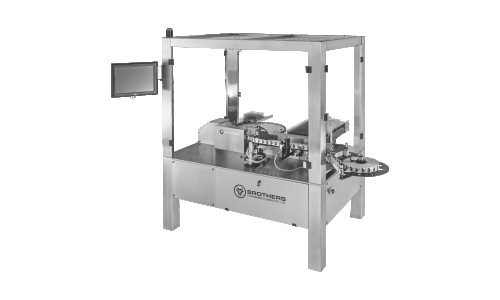

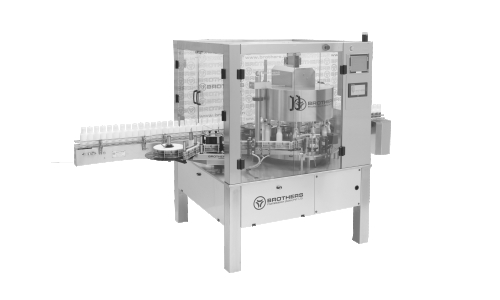

Rotary Labelling Machine

Innovating Excellence in Rotary Labelling Solutions for Over 50 Years

Brothers Pharmamach (India) Pvt. Ltd. stands as a trusted leader in the manufacturing of cutting-edge Rotary Labelling Machines and advanced solutions for industries worldwide. With a rich legacy spanning over five decades, the company has been at the forefront of revolutionizing labeling processes. Supported by a team of 300+ skilled engineers, Brothers Pharmamach specializes in delivering precision and efficiency, ensuring unmatched quality and customer satisfaction.

Their flagship product line, including Rotary Sticker Labelling Machine for Round Bottles, is designed to cater to the diverse needs of global industries. Whether it's pharmaceutical, food & beverage, cosmetics, or other sectors, these machines guarantee seamless operations and error-free labeling. From compact containers to diverse bottle shapes, the Rotary Bottle Labeling Machines offer unparalleled accuracy and speed.

With over 100,000 satisfied clients and exports to 45+ countries, Brothers Pharmamach has successfully served more than 5,000 industries, earning a reputation for reliability and innovation. The Rotary Bottle Sticker Labelling Machines are engineered with advanced features, ensuring enhanced productivity and seamless integration into production lines.

Choose Brothers Pharmamach for high-performance labeling solutions that empower your business. Their commitment to excellence, paired with cutting-edge technology, sets the benchmark for the industry. Experience the perfect synergy of innovation, reliability, and precision.

A Rotary Labelling Machine is an automated system used for high-speed and precise labelling of bottles, containers, and packaging in industries like pharmaceuticals, food & beverage, cosmetics, and chemicals.

Our Rotary Labelling Machines can apply various labels, including self-adhesive (sticker) labels, wet glue labels, wrap-around labels, and transparent labels, ensuring flexibility for different packaging needs.

Yes, our Rotary Labelling Machines are designed to accommodate bottle shapes and sizes, making them adaptable for different production lines.

Regular maintenance includes cleaning the labelling heads, checking for wear and tear, and ensuring proper alignment. Brothers India provides technical support and after-sales service for smooth operations.

×

×