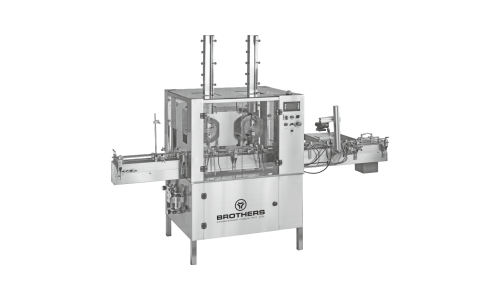

AHLI-150

Leaflet / Outserter Pasting Machine

High Speed Leaflet Pasting Machine

PRODUCT OVERVIEW

The Automatic High Speed Twin Head Leaflet / Outserter Pasting

Machine Model AHLI-150 , is suitable for Round, Rectangular or

Square Shape Bottles with maximum speed of 140 Bottles per minute

to apply Leaflet on Top Side of Bottles. Specially Machine construction

in completely Stainless Steel finish including machine frame structure

with Stainless Steel Enclosures.

The Machine is suitable for applying various Sizes and thickness of

Leaflet on Bottles with speed upto 140 bottles per minute depending on

Bottle Diameter, Bottle Height and Leaflet Size for use on Tablet Bottle

Packing Line for Online operation. Machine can Paste / Fix the Leaflet

on Top of the Bottles. Machine can be connected with any Bottle

Packing Line for using it online. Machine suitable for various sizes of

Bottles as well as Leaflet.

Machine does not require change parts for change in bottle size

and Leaflet size. Customer may require few items for any special size

of leaflet as a change parts.

Special Machine can also be designed to apply leaflet on body of bottles

on request from customer. Machine with various optional as well as

Standard features, and with unique features of No Glue No Leaflet

system. Machine available with Online Hot Melt Gluing System as a

optional items, if require we can supply the machine without online

gluing system also.

TECHNICAL SPECIFICATIONS

| Bottle Diameter | Up to 125mm* and other shape on request |

| Bottle Height | Up to 225mm* |

| Leaflet Size | Samples required |

| Conveyor Height | 815-850 mm |

| Overall Dimensions | 2980 mm (L) x 770 mm (W) x 2200mm (H) |

| Speed | Max. 140 Bottles per minute depending on Bottle and Leaflet Size |

| * Specification can be changed as per customers requirements | |

AHLI-150 - High Speed Leaflet Pasting Machine

SPECIAL FEATURES

- Colour Touch Screen Operation Panel

- No Air - Machine Stop System

- Machine works on Compressed Air - No Vacuum required

- No Bottle - No Leaflet Pasting System

- No Glue - No Leaflet Pasting System

- No Leaflet in feeder - Machine Stop System

- Machine construction in Stainless Steel Finish

- Single Drive synchronizing operation of Conveyor, Bottle Feeding and Leaflet Pasting

- Minimum Change over time

- No Change Parts for Change in Bottle Size and Leaflet Size. Leaflet Sample require to workout any extra change parts if required due to special size of leaflet.

OPTIONAL FEATURES

- Online Camera System for detection of Missing Barcode/Pharmacode/2D code or Leaflet on Bottle

- Online Bottle Rejection System for Wrong Leaflet or Missing Leaflet

- Stainless steel construction Safety Cabinet with Toughened Glass or Acrylic

- Hot Melt Gluing System for Online Glue Application

UTILITY REQUIREMENT

| Filtered Compressed Air | 7 Bar Air Pressure |

| Electrical | 415 VAC 3 Phase 50Hz and 220 VAC Single Phase Power Supply (50/60 Hz) with A.C. Drive |

| Power | 2 Hp |

Other Available Models

| AHLI-150 | AHLI-120R | AHLI-60S | OCTOPUS-300 |

×

×