Automatic Table Top Capsule Filling Machine

PRODUCT OVERVIEW

BUILT-IN UNIQUE FEATURES

- Totally enclosed operation, safety guard

- Best Suitable for R6D Lab, Process Development Lab, small production Capacity Trial Research and small Batch Production

- All Stainless Steel Product contact Parts made from Ss316 Material

- Precise Dosing system having Tamping Pin System for better yield

- Suitable to use for various capsule size with help of change parts

- Built in colounouch Screen control system

- Machine with Powder and Pellet Filling

- Auto Rejection of unopened capsule

- Change over time appx. 50 minutes

- No Special Tool required for Change over

- No vaccum Pump Required

- Tablet Attachment with NFD (Non Filling Detection)*

- Liquid Filling attachment*

- Partial Filling attachment*

- 15" Touch Screen PC operation with 21CFR Part 11 compliance*

- CE certification*

Output capacity

- Max.3000 Capsule/hr - Power

- Max.3000 Capsule/hr - Pellet

- Max.2000 Capsule/hr - Tablets

Possible dosing combination

- Power

- Micro Tablet

- Power + Pellet

- Power + Tablets

- Pellet + Tablets

- Machine Operation Principle : Tamping Pin

Machine Speed calculation:

- Minimum Speed - 25 SPM * 60 Min = 1500 Capsule / Hour

- Minimum Speed - 50 SPM * 60 Min = 3000 Capsule / Hour

- Available Capsule Sizes : #OO, #O, #OEL, #1, #2, #3, #4

- Method Of Speed Control : HMI Control (Optionally 21CFR Part11 Compliance, CE Certifield)

Method of Weight Control : Dosing Disk Thickness

- #OO - 24.0mm Max

- #O - 21.5mm Max

- #OEL - 21.5mm Max

- #1 - 20.0mm Max

- #2 - 18.5mm Max

- #3 - 16.5mm Max

- #4 - 15.0mm Max

Number Of Segments : 08 Segments

(08 Each upper and lower segments to have holes respetively)- Air Compressor : 4-6 bar

- Machine Dimensions in mm : D 665 * W 800 * H 1000

- Case Dimensions : D 780 * W 900 * H 1100 appx

- Net Weight : Approx 270kg

- Shipping Weight : Approx 350kg

working condition

- Storage of capsule Temperature:

- About 20 ~ 25 Degree Celsius

- Relative Humidity: About 50 %

- Temperature : About 20 ~ 25 Degree Celsius

- Relative Humidity : About 40 ~ 50 %

- Powder granularity : 40-80 mesh (Optional)

OUR PRODUCTS

OUR PRODUCTS

Washing Machine

Wide Ranges of Bottle Washing Machine, Vial Washing Machine, Airjet Cleaning Machine, Jars Cleaning Machine with various speeds and features.

VIEW PRODUCTS

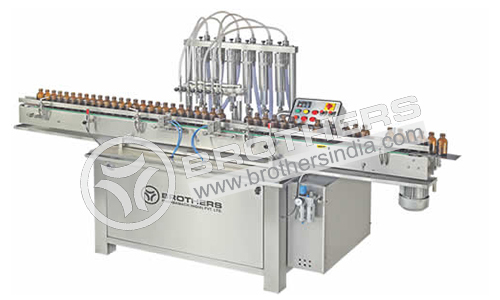

Filling Machine

We have a wide range of Liquid Filling Machines, Powder Filling Machines, Viscous Filling Machine, with various features and ouput.

VIEW PRODUCTS

Capping Machine

ROPP/Aluminum Cap Sealing Machine, Lug Capping Machine, Pick N Place Screw Capping Machine, Vial Cap Sealing Machine for various Cap Application.

VIEW PRODUCTS

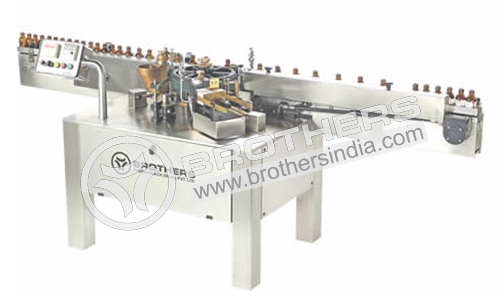

Labelling Machine

Wide Ranges of Wet Glue Labelling Machine and Sticker Labelling Machine for different application for Food, Beverages, Pharmaceutical, Chemicals, Herbals, FMCG, etc.

VIEW PRODUCTSCompany profile

We at Brothers Pharmamach believe, it's the "men behind the machines" who have caused all the acceleration.

FIND OUT MORE

Products & Solutions

We have been strengthening its positions as the Pioneer in the Packaging Machine Manufacturing.

FIND OUT MOREAcross The Globe

Aligning with the latest trends in packaging industry, the company has introduced a series of economical Machines

FIND OUT MORE

Strong Experience

Backed up by a dynamic leadership, efficient management and an exceptionally dedicated technology savvy team.

FIND OUT MORE

JOIN THE CONVERSATION