Complete Guide to Bottle Capping Machines – Types, Uses & Applications

Related Blogs

In the fast-paced world of pharmaceutical, cosmetic, and FMCG manufacturing, precision and speed are critical. One essential piece of equipment that ensures product integrity and packaging efficiency is the bottle capping machine. Whether you're sealing bottles of syrup, lotion, or liquid disinfectant, choosing the right capping solution can significantly impact your production quality and throughput.

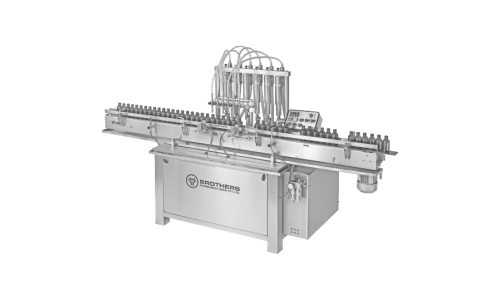

This guide explores the types, uses, and applications of bottle capping machines, with a spotlight on the latest models from Brothers Pharmamach India Pvt. Ltd.—a leading manufacturer of packaging machinery based in Ahmedabad, Gujarat.

What is a Bottle Capping Machine?

A bottle capping machine is designed to securely apply caps, lids, or closures onto bottles of various shapes and sizes. These machines ensure leak-proof sealing, tamper resistance, and consistent torque application. Depending on production needs, manufacturers can choose between manual bottle capping machines, automatic bottle capping machines, or compact small bottle capping machines.

Types of Bottle Capping Machines

1. Manual Bottle Capping Machine

Ideal for small-scale or startup operations, the manual bottle capping machine offers simplicity and cost-effectiveness. It allows operators to manually place and tighten caps on bottles. Despite its compact design, it delivers consistent torque and is suitable for laboratories or pilot production units. Brothers Pharmamach’s manual cappers are ergonomically designed for easy handling and can accommodate various cap types such as screw caps, ROPP caps, or snap-on closures.

2. Semi-Automatic Capping Machine

For medium production volumes, semi-automatic capping machines provide the right balance between automation and flexibility. Operators manually load bottles and caps, while the machine automatically applies the tightening torque. These machines are ideal for small to mid-size companies looking to improve productivity without major investment in full automation.

3. Automatic Bottle Capping Machine

When it comes to large-scale, continuous production lines, the automatic bottle capping machine is the most efficient choice. It is equipped with automatic cap feeding, bottle positioning, and torque control systems to ensure consistent sealing at high speeds. Brothers Pharmamach’s automatic capping machines integrate seamlessly with bottle filling and labeling lines, reducing downtime and increasing throughput. They are designed to handle multiple cap types and bottle sizes with quick changeover features.

4. Small Bottle Capping Machine

For industries dealing with smaller containers, such as vials or cosmetic bottles, the small bottle capping machine provides precise sealing without damaging delicate bottles. Compact and energy-efficient, these machines are ideal for space-constrained production areas. The model range from Brothers Pharmamach ensures smooth operation, accuracy, and minimal product wastage — crucial for pharmaceutical and cosmetic packaging.

Key Features of Brothers Pharmamach Capping Machines

- Sturdy Construction: Built with high-quality stainless steel for durability and GMP compliance.

- User-Friendly Interface: Equipped with digital control panels for speed and torque adjustments.

- Versatile Design: Compatible with various cap and bottle types including ROPP, screw, press-fit, and flip-top caps.

- High Efficiency: Delivers consistent torque, minimizing capping defects and ensuring leak-proof seals.

- Easy Maintenance: Simple design with minimal moving parts for effortless cleaning and servicing.

These machines are designed to meet international quality standards and are suitable for industries with stringent hygiene requirements, especially pharmaceuticals and food processing.

Applications of Bottle Capping Machines

- Pharmaceuticals: For sealing syrups, tonics, and tablet containers to prevent contamination.

- Food & Beverages: Used in capping bottles of sauces, juices, and dairy products.

- Cosmetics & Personal Care: Ideal for sealing shampoo, lotion, and essential oil bottles.

- Chemicals & Agro Products: For securely sealing containers with liquids, powders, and cleaning agents.

Why Choose Brothers Pharmamach India Pvt. Ltd.?

With decades of experience in the packaging machinery industry, Brothers Pharmamach India Pvt. Ltd. has become a trusted name worldwide. The company’s latest models of capping machines feature advanced automation, servo-driven torque control, and quick-change mechanisms, ensuring consistent performance and maximum uptime. Whether you need a manual, semi-automatic, or automatic bottle capping machine, Brothers Pharmamach offers customized solutions to meet your production goals.

×

×