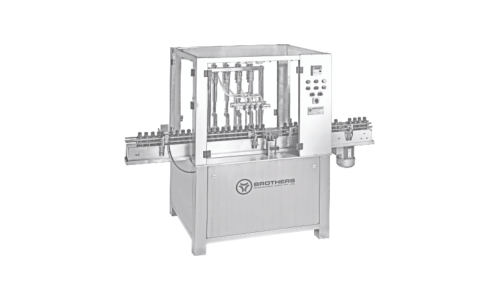

LIQFILL-80FM

Liquid Filling Machine

Automatic Four Head Volumetric Liquid Filling Machine

PRODUCT OVERVIEW

The Automatic Four Head Volumetric Linear Liquid Bottle Filling Machine, Model LIQFILL-80FM is suitable for Bottles with maximum speed of 80 Bottles per minute. The output of Bottle Filling Machines depending on nature of Liquids, Bottle Diameter, Bottle Height, Bottle Neck Size and Fill Volume. Machine construction in fully Stainless Steel finish including machine frame structure. Machine with Optional Turn Tables at In-feed and Out-feed with individual drives to match the speed of incoming and outgoing Bottles for smoother operation. All parts coming in contact with Liquids are made from SS316 Materials.

TECHNICAL SPECIFICATIONS

| Bottle Diameter | Upto 90mm* |

| Fill Range | 30ml to 500ml with help of Change Parts / Syringe |

| Accuracy | +/- 1% Depending on Liquid with Single Dose |

| Electrical | 220 VAC Single Phase Power Supply (50 Hz) |

| Power | 2.0 Hp |

| Speed | Max. 80 Bottles per minute |

| Syringe Fill Range | 10ml to 50ml,50ml to 100ml, 100ml to 250ml and 250ml to 500ml |

| Conveyor Height | 800-850 mm |

| Overall Dimensions | 1830 mm (L) x 800 mm (W) x 1550 mm(H) |

| * Specification can be changed as per customers requirements | |

LIQFILL-80FM - Automatic Four Head Volumetric Liquid Filling Machine

SPECIAL FEATURES

- No Bottle - No Fill System, No Bottle - Machine Stop System

- All contact parts made of SS316 material with easy removal system for Auto-Claving/Sterilization/Cleaning

- Machine construction in SS 304 material

- Optional Diving Nozzle for Foam free filling available on request

- Very High Fill Accuracy

- Automatic In-feed and Exit of Bottles

- Minimum Change Over time

- Unique Free Spinning Bottle Separator- No pneumatic operation

- Built-in A.C. Variable Freq. Drive System

×

×