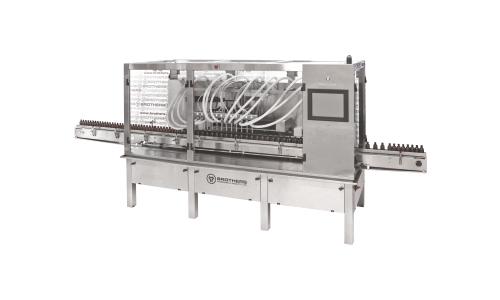

LIQFILL-250-MOTION

Liquid Filling Machine

Automatic Twelve Head Volumetric Liquid Bottle Filling Machine

PRODUCT OVERVIEW

The Automatic Twelve Head Motion based Volumetric Linear Liquid Bottle

Filling Machine, Model LIQFILL-250-Motion is suitable for Bottles with

maximum speed of 300 Bottles per minute. The output of Bottle Filling

Machines depending on nature of Linear Syrup Filling Machine, Liquids, Bottle Diameter,

Bottle Height,

Bottle Neck Size and Fill Volume.

Machine with unique Motion filling system, Filling Nozzle moves

alongwith Bottles during the Liquid Filling Process without stoppage of

Bottles ensuring trouble free operation with higher speed compare to

conventional fix nozzle type filling machine. Machine construction in fully

Stainless Steel finish including machine frame structure.

Machine with Optional Turn Tables at In-feed and Out-feed with individual

drives to match the speed of incoming and outgoing Bottles for smoother

operation. All parts coming in contact with Liquids are made from SS 316

Materials.

TECHNICAL SPECIFICATIONS

| Bottle Diameter | Upto 70mm* |

| Bottle Height | 50mm to 200mm* |

| Fill Range | 10ml to 50ml or 30ml to 100ml or 100ml to 250ml* with the help of Change Parts / Syringe. |

| Accuracy | +/- 1 % |

| Speed | Maximum 300 Bottles per minute depending on Fill Volume and type of Liquid and Bottle Shape/Size. |

| Conveyor Height | 800-850 mm |

| Overall Dimensions | 3625 mm (L) x 1125 mm (W) x 1800 mm(H) |

| * Specification can be changed as per customers requirements | |

UTILITY REQUIREMENT

| Filtered Compressed Air | 5 to 7 Bar Air Pressure Required Suitable Capacity Buffer Tank |

| Electrical | 220 VAC Single Phase Power Supply (50 Hz) |

| Power | 5.0 H.P. |

SPECIAL FEATURES

- Linear Motion Filling System for Smoother and Faster Operation

- Built in PLC with Colour Touch Screen Operation.

- No Bottle - No Fill System,

- No Bottle - Machine Stop System

- Synchronize Movement of Bottle and Filling Nozzle for continuous operation

- All contact parts made of SS316 material with easy removal system.

- Diving Nozzle System

- Very High Fill Accuracy of +/- 1%.

- Suitable For Syrup and Suspension having higher viscosity.

- Automatic Infeed and Exit of Bottles

- Minimum Change Over time

- Built-in A.C. Variable Freq. Drive System

- Fully Stainless Steel Finish * All Features mentioned above may not be part of standard machine, please check your requirement.

×

×