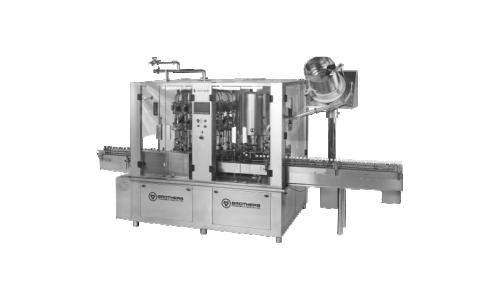

LIQFILL-150FM

Liquid Filling Machine

Rotary Monoblock 16x8 Head Liquid Filling & Capping Machine

PRODUCT OVERVIEW

The Automatic Rotary Monoblock 16x8 Head Liquid Bottle Filling and

Capping Machine, Model LIQFILL-150FM with FLOW METER Liquid

Filling Technolgy is suitable for Round, Oval, Flat or Square Bottles with

maximum speed of 120 Bottles per minute.

Machine available with ROPP / Plastic SCREW Capping system or Pick

N Place type CRC Screw Capping System.

Machine with Rotary operation of bottles resulting in smoother

movement of bottles at lower speed producing higher output. The output

of Bottle Filling Machines depending on nature of Liquids, Bottle

Diameter, Bottle Height, Bottle Neck Size and Fill Volume. Machine

construction in fully Stainless Steel finish including Heavy Duty M.S.

Frame structure with S.S.304 cladding. Machine with Optional Turn

Tables at In-feed and Out-feed with individual drives to match the speed

of incoming and outgoing Bottles for smoother operation. All parts

coming in contact with Liquids are made from S.S. 316 Material.

Machine does not require any change parts for change in Fill Volume

due to Flow Meter Technology, which helps user to set the required fill

volume directly from Machine control panel Touch Screen system.

Machine new technology also offers simple user friendly operation with

less moving parts coming in contact with liquid and also higher level of

accuracy for filling liquid.

TECHNICAL SPECIFICATIONS

| Bottle Diameter | 28mm to 70mm* |

| Bottle Height | 50mm to 200mm* |

| Fill Range | 15ml to 500ml* |

| Cap Size | 18mm to 55mm Diameter |

| Speed | Upto 120 Bottles per minute depending on Fill Volume and type of Liquid |

| Conveyor Height | 900-950 mm |

| Overall Dimensions | 3800 mm (L) x 1570 mm (W) x 2225 mm(H) |

| Compressed Air | Required 5 to 7 Bar Air Pressure to be provided by customer only |

| * Specification can be changed as per customers requirements | |

UTILITY REQUIREMENT

| Filtered Compressed Air | 5 to 7 Bar Air Pressure Required Suitable Capacity Pressure Pump |

| Electrical | 440VAC 3 Phase / 220 VAC Single Phase Power Supply (50 Hz) |

| Power | 5.0 Hp |

SPECIAL FEATURES

- FLOW Meter for High Fill Accuracy and Repeatability

- Electronically controlled Volume settings through HMI, No Mechanical settings required

- Built in PLC with Colour Touch Screen Operation.

- No Bottle - No Fill System,

- No Bottle - Machine Stop System

- Rotary Bottle Movement for smoother operation

- All contact parts made of SS316 material with easy removal system.

- Very High Fill Accuracy of +/- 1 to 1.5ml for any fill volume upto 250ml and +/- 2ml above 250ml Pack Size.

- Machine also available with option of high fill accuracy of +/- 0.5 to 1ml

- Suitable For Syrup and Suspension having higher viscosity.

- Automatic Infeed and Exit of Bottles

- Minimum Change Over time

- Built-in A.C. Variable Freq. Drive System

- Fully Stainless Steel Finish

- Simple Change over for different size of Bottles with No Change Parts system for Different Fill Volume

- Built in A.C. Variable Frequency Drive System.

- Suitable to Handle ROPP as well as Normal SCREW Cap with help of change parts

- Machine also available with Pick N Place SCREW capping for CRC/Special caps.

- Filling and Capping operation in Single machine due to Monoblock design

- Special 3 in 1 Model also available having ROPP as well as Plastic Screw Capping Station

- All Features mentioned above may not be part of standard machine, please check your requirement.

×

×